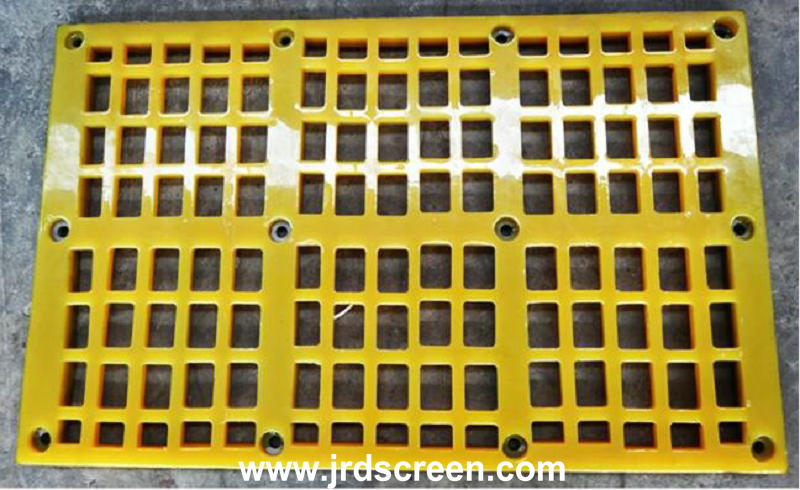

Polyurethane Rinsing Screen Is A Good Substitute For Wire Mesh Screen Medium. Its Main Advantages Are Excellent Wear Resistance, Non-Corrosiveness And Low Noise. They Provide Perfect Constant Screening Performance, No Mixed Cracks And No Cracks Under Vibration. In Addition, Polyurethane Sheets Are Repairable.

Compared With Braided Yarn, The Service Life Of Urethane Rinsing Screen Can Be Prolonged By 10 Times. As a Result, It Reduces Operating And Labor Costs. On The Other Hand, The Flexible Structure Allows The Screen To Bend, Which Helps To Reduce Blockages. In The Long Run, Lower Weight Can Also Help Reduce Energy Consumption.

Our PU Rinsing Screen Can Be Used Instead Of Wire Mesh Without Any Modification Of The Mesh Box.

Polyurethane Rinsing Screen Is A New Product Developed In Recent Years, Which Is Used To Replace Metal Rinsing Screen On The Screen Machine Of Ore Dressing, Classification And Dehydration.

It Is Mainly Used For Classification, Screening, Dehydration And Other Places Of Various Ores Such As Coal Mine, Iron Ore, Copper Mine, Gold Mine, Etc. It Is One Of The Necessary Accessories Of Vibrating Screen.

Due To The Service Conditions Of Rinse Screen, Not Only Wear-Resistant, Corrosion-Resistant And Aging Resistant, But Also Accurate Mesh And Seam Size Must Be Kept In Use. In The Past, Stainless Steel Was Mainly Used To Rinsing Screen. However, Due To The Poor Wear Resistance, Elasticity And Corrosion Resistance Of Metal Rinsing Sieve Screen, Large Noise, High Processing Cost And Short Service Life, Most Of Them Are Replaced By Polyurethane Rinsing Screen.

Compared With The Metal Sieve Plate, The Polyurethane Rinsing Screen Gives Full Play To The Features Of Polyurethane Such As High Wear Resistance, High Elasticity, Sound Absorption, Shock Absorption, Etc, It Has The Advantages Of Convenient Processing, Good Wear Resistance, Long Service Life, High Screening Quality, Strong Self-Cleaning Ability, Good Screening Performance, Noise Reduction, Improvement Of Operating Environment, Wide Application Range (Dry Material, Wet Material, Raw Ore, Crushed Ore And Other Materials With Different Particle Sizes), Etc., So It Has a Good Prospect To Replace Metal Screen Plate Or Ordinary Rubber Screen Plate With Polyurethane Rinsing Screen.

It Mainly Consists Of Relaxation Sieve Plate, Tension Sieve Plate, Large Hole Sieve Plate, Slit Sieve Plate And Other Series. Its Processing Is Mainly Made Of Liquid Reaction Injection Molding Technology, Atmospheric Pressure Casting And Vulcanization.

Advantages Of PU Rinsing Screen:

Compared With The Steel Wire Mesh, The Service Life Can Be Prolonged By 10 Times.

No Matter The Degree Of Wear Or Tear, The Sieve Opening Size Remains Unchanged.

Low Noise Level

Strong Impact Resistance

Minimum Screen Opening Is Much Smaller

Flexible Structure

Low Friction Coefficient

Oil, Acid And Corrosion Resistant Chemicals

Rinsing Screen Area:

Aggregate Plant

Mining Applications

Sand And Aggregate Flushing

Food Industry And Flour Mills

Asphalt Production

Agriculture And Fertilizer Industry

Coal Processing

Slag Processing

Contact: Eric Song

Phone: +86-16633372827

Tel: +86-166-33372827

Email: sales@polyurethanescreenpanels.com

Add: No.300.Hengdong Road Decheng Zone Dezhou ShanDong China