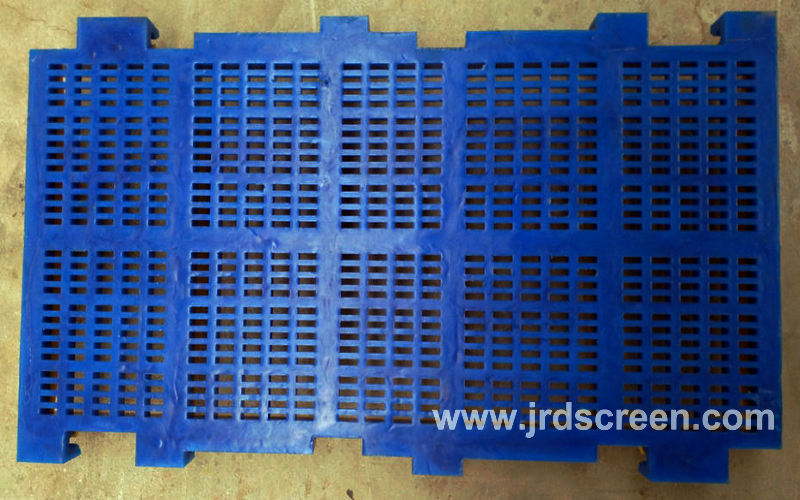

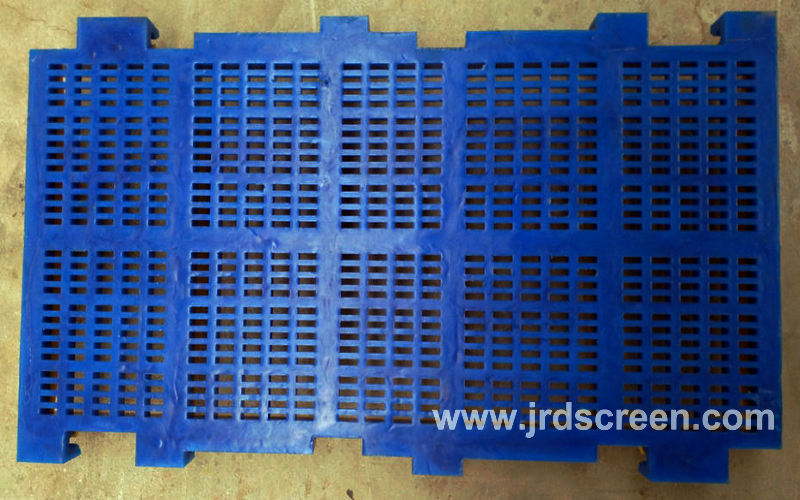

Polyurethane Edged Screen ( PU , Urethane ) Sieve Screening

Polyurethane Edged Screen Refers To The Metal Mesh Of Different Types, Which Is Cut To The Size, Specification And Shape Required By The User According To The Requirements Of The Customer / Drawing. Polyurethane Elastomer With Different Colors Is Used For Edge Coating, Which Can Make The Whole Mesh Plate Obtain Elasticity, Shock Absorption And Noise Reduction Through Polyurethane.

Due To The Isolation And Buffer Of Polyurethane, The Damage Of Working Strength To The Machine Is Relieved And The Environmental Protection Is Improved. At The Same Time, The Details Of Polyurethane Binding Can Be Processed, And Positioning Screws Or Pin Holes Can Be Installed To Facilitate The Use And Installation.

Polyurethane Edging Screen Be Made Of High Quality Polyurethane And Good Tensile Embedded Metal Skeleton. It Combined With Wear Resistance Polyurethane And High Tensile Strength Steel Frame Work , It Can Be Good Used In Separating And Mining Screening Industry.

Screen Connection Types

Bolts Connection

Mosaic Connection

Press Bar Connection

Hook Connection

So Many Connection Types Can Be Used For Different Machines Applications. It Is The Most Versatile And Cost Effective Modular System.

Specifications

Material: Polyurethane , Metal Frame.

Thickness: 10mm - 100mm.

Aperture Type: Square, Rectangular , Round.

Aperture Size: 2mm - 80mm.

Features:

Polyurethane Materials For Wear Resistance.

Self-Cleaning Apertures Reducing Pegging And Blinding.

Wide Range Apertures Suit Most Applications.

Various Panel Sizes To Suit All Vibrating Screens.

Different Connection Type For Easy Installation And Replacement.

High Screening Performance.

Low Noise.

Long Service Life And Durable.

Applications:

It Can Fit Various Vibrating Screens. It Is Widely Used In Various Applications.

Steel Plants.

Mining Industry.

Cement Plants.

Mineral Industry.

Power Plants.

Coal Washing.

Sand, Gravel Separating And Screening.