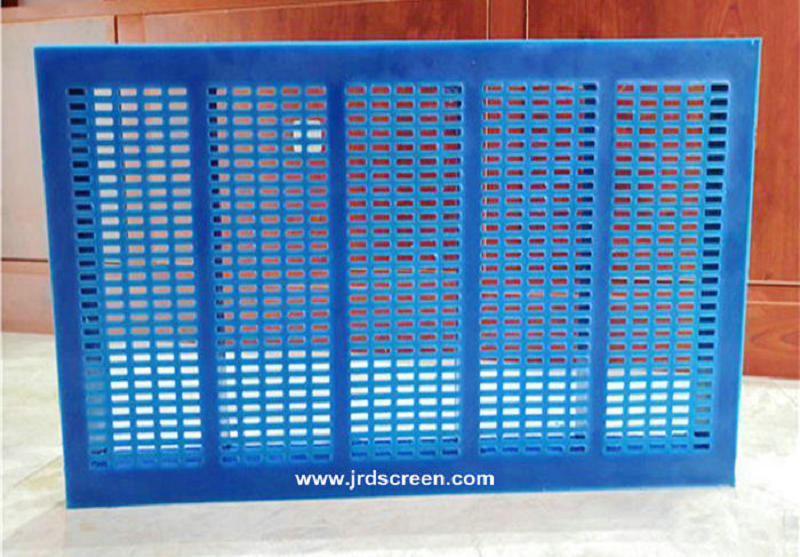

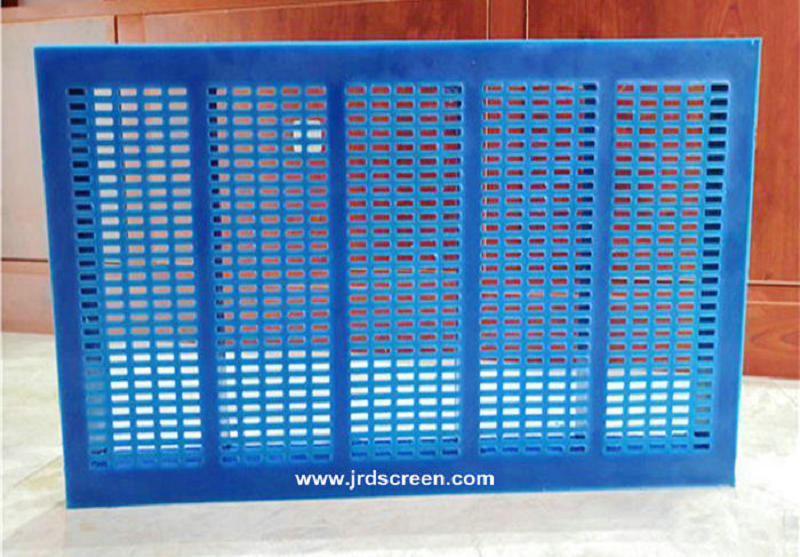

Polyurethane Rectangular Screen ( PU , Urethane ) Sieve Screening

Polyurethane Rectangular Screen Is Made Of Wear-Resistant Polyurethane Elastomer By Casting, With The External Dimension Of Rectangular Polyurethane Screen. Rectangular Screen Can Be Installed On The Vibrating Screen By Splicing, And The Connection Methods Are Pin, Screw, Clamp, Pressing Plate, Etc.

Most Of The Structures Are Built-In Structures With Steel Framework. First, The Carbon Steel Framework Is Made Into a Rectangle, Which Is Installed In The Polyurethane Casting Mold, And Then Polyurethane Casting Is Carried Out To Form a Rectangular Screen With Steel Framework Embedded And Polyurethane Wrapped.

Polyurethane Rectangular Opening Screens Work Under The Conditions Of The Water As The Medium, And In The Case Of Water, Oil Media, The Friction Coefficient Of The Polyurethane Materials Is Lower And More Favorable Through The Sieve To Improve The Screening Mesh Efficiency, And Avoid The Wet Particle Adhesion, Due To The Lower Coefficient Of Friction, Wear Reduction In Service Life.

Screens Feature :

Manufactured Individually And Specific To The Application

Long Lifetime

By Hot Casting, According To Screened Material And Machine Dimensions

With Hardness Settings 55, 65, 75, 85 An 90 Shore A

Rectangular Hole Width

Conical Hole Shapes To Prevent Materials From Sticking In The Holes

Slotted Holes For Dewatering, Longitudinal Holes For Difficult Materials

Blind Zones And Reinforcements In The Material Application Area

Retaining Strips And Deflectors To Improve Screening