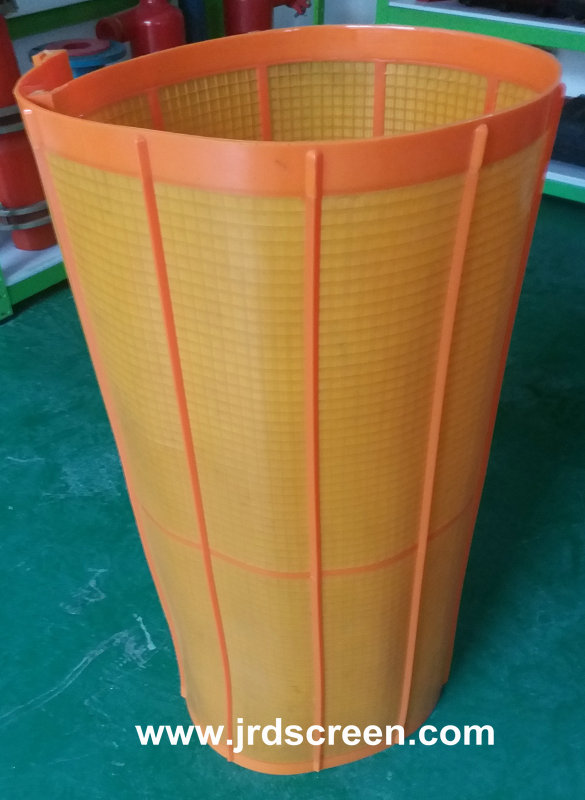

Polyurethane Fine Screen Is The Core Part Of Fine Screen Machine. It Is The Main Screening Part Of The Whole Machine, Mainly In Contact With The Material, Separating The Size Of Particles. Therefore, The Quality Of Polyurethane Fine Screen Directly Affects The Screening Efficiency And Screening Performance.

Our Patent Design Of The Integrated Forming Screen, Performance Is Far More Than The Traditional Splicing Fine Screen. Because There Is No Splicing, The Wear-Resistant Coefficient Is Increased, So That The Service Life Is Longer, Blindness Is Prevented, And Leakage Is Not Allowed.

It Improves The Mineral Recovery Rate. When The Large Particles Are Separated Into The Circulation Bin, They Can Be Grinded More Finely, So As To Carry Out The Secondary Screening. It Is Widely Used In Screening And Processing Of Metal And Nonmetal Minerals.

Fine Screen Size

Screen Size: 1045x700mm

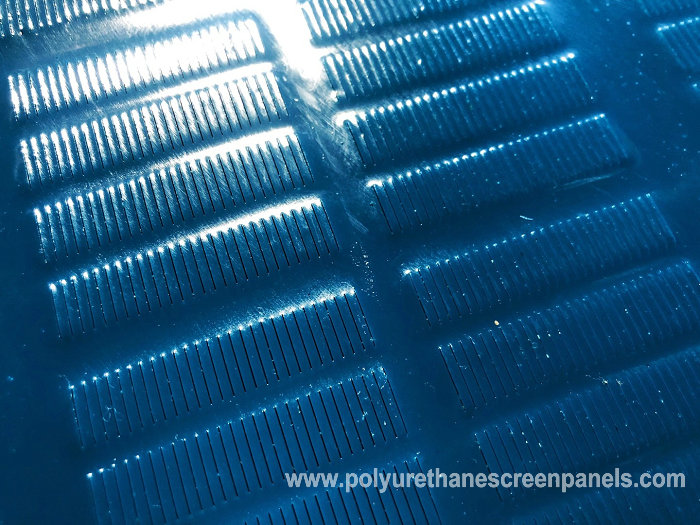

Opening Size: 0.075mm

Normal Service Life: 6-12 Months

Material: Polyurethane Material

For Fine Screen Machine.

Features

High Opening Area 35% - 45%

Polyurethane Fiber Reinforced One-Piece Molding Technology To Prevent Cracking And Improve The Tensile Strength And Service Life Of The Screen

Anti Glare Tapered Aperture Design Improves Screening Performance And Efficiency

For Mineral Processing Applications

Our Separation Polyurethane Fine Screen Is The Right Choice For Your Existing Screening Machine, And a Strong Technical Sales Team Will Escort Your Screening Work.

PU Fine Screen For Ore And Coal Sieve

Mini Aperture:0.15mm

High Opening Rate

Aperture Width (mm): 0.10,0.12,0.15,0.18,0.2,0.3,0.4,0.5,0.7,1.0,

Aperture Length (mm): 2.12 ,2.59 ,2.75 ,4.30 ,5.75

Opening Rate: 25-30%

Life Span: 6 Months

Outer Dimensions: Nominal Width(mm): 600,800,1000,1200,1400,1600

Nominal Length (mm):700,800,1000,1200,1500,2000,2500,3000,3500

Depending On The Installation Requirements, Both Ends Of Screen Can Be Made With Hook Or Without Hook.

Fine Screen Efficiency

Because The Porous Polyurethane Material Of Polyurethane Fine Screen Is Strong, Large Cone Angle (140 Degrees). Therefore, The It Can Effectively Prevent The Adhesion Of Moist Fine Particles, Therefore Suitable For The Classification Of Polyurethane Fine Sieve Moist Material.

The Self-Cleaning Performance Of The Surface Is High

No Plugging Of Fine Sieve Mesh

High Sieveing Efficiency Of Fine Screen

In Our Factory, The PU Fine Screen Is Made Of High Quality Polyurethane, And The Of The Polyurethane Elastomer Has Good Tensile Property, And It Can Effectively Avoid The Phenomenon Of Plugging In The Dynamic Situation

Scope Of Application

The Scope Of Application Of Vibrating Polyurethane Fine Sieve Is Very Extensive. It Involves Almost All Aspects Of Life. All Kinds Of Fine Screen Need To Be Used In Processing And Manufacturing.

It Is Mainly Used In Mining, Coal, Smelting, Building Materials, Refractory Materials, Light Industry, Chemical Industry, Medicine, Food And Other Industries.

It Is Most Used In Mineral Processing Plant

According To Its Transmission Mechanism, It Can Be Divided Into The Following Types: Eccentric Polyurethane Fine Screen, Inertia Fine Screen, Self Centering Fine Screen And Resonance Fine Screen.

Contact: Eric Song

Phone: +86-16633372827

Tel: +86-166-33372827

Email: sales@polyurethanescreenpanels.com

Add: No.300.Hengdong Road Decheng Zone Dezhou ShanDong China