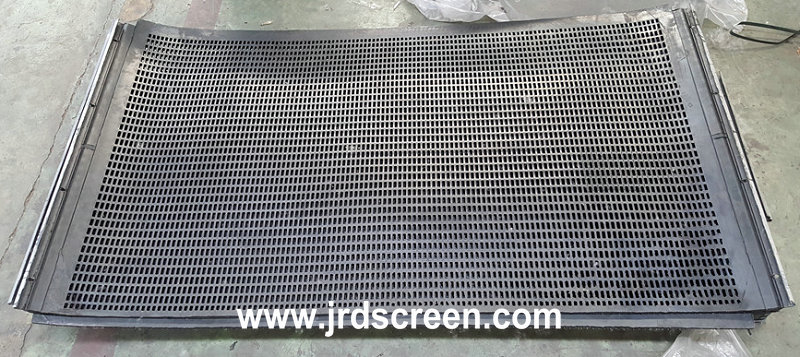

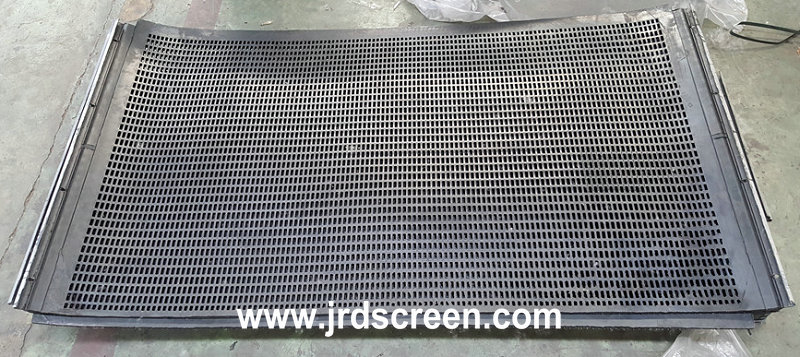

Rubber Tensioned Screen Media Is Most Suitable For Medium To Fine Screen Application. The Use Of Rubber Will Reduce Noise, Reduce Clogging, And Provide Special Wear Resistance. The Rubber Cross Tension Media Is Made Of Two Layers Of High Quality Wear-Resistant Rubber With Tire Cord Reinforcement Between Layers.

The Thinner Screen (3, 5, 7, 10 And 15 mm Thick) Has A Single Layer Of Fabric Reinforcement, While The 20, 25 And 35 Mm Thick Screen Has Two Layers. Polyester Fabric Reinforcements Allow Correct And Sustained Media Tension.

Advantages :

Some Advantages Of Rubber Tension Screen Over Other Screening Media Include:

Screens For Most Manufacturers

Highly Flexible - Reduces Nailing And Clogging - Improve Layering

Reduce Noise Pollution

Suitable For Various Applications

Our Rubber Tension Sieve Media Is Very Suitable For High Frequency Screen With Longitudinal Support Rod. They Are Effectively Used In Primary, Secondary And Tertiary Screening Applications As Well As In Drum Screening.

Note: All Rubber Cross-Tension Screen Media Can Be Converted To Modular Screen If Necessary.

Rubber Screen Media Raw Materials Can Be Divided Into Natural Rubber And Synthetic Rubber. The Raw Material Of Rubber Media Is Natural Wear-Resistant Rubber, Which Is Directly Extracted From Rubber Trees, Rubber Grass And Other Plants.

After Processing, Rubber Raw Materials Have Special Properties Such As Elasticity, Insulation, Impermeability And Air. It Belongs To High Elastic Polymer. Synthetic Rubber Is Synthesized From Various Monomers. Rubber Tension Screen Products Are Widely Used In All Aspects Of Industry Or Life.

Screen Media Materials Choose:

1, Natural Rubber NR

2, Styrene Butadiene Rubber SBR

3, Butyl Rubber IIR

4, Hydrogenate Nitrile Rubber HNBR

5, Ethylene Propylene Rubber EPDM

6, Nitrile Rubber NBR