Rubber Shaker Screen Bends Is A Panels-Shaped Wear-Resistant Product With Various Meshes, Which Is Made By Pressing Rubber With Flat Vulcanizer. The Rubber Mostly Adopts Super Wear-Resistant Rubber With High Elasticity. Widely Replace Stainless Steel Wire Screen, With Strong Seismic, Buffer, Corrosion Resistance, Wear Resistance, Self-Cleaning And Other Excellent Features. The Mesh Is Mostly Wedge-Shaped, Which Can Fully Improve Screening Efficiency, Slow Down The Generation Of Working Noise, And Improve The Comfort Of Working Environment. It Shows Excellent Characteristics In The Screening System In Dry Environment.

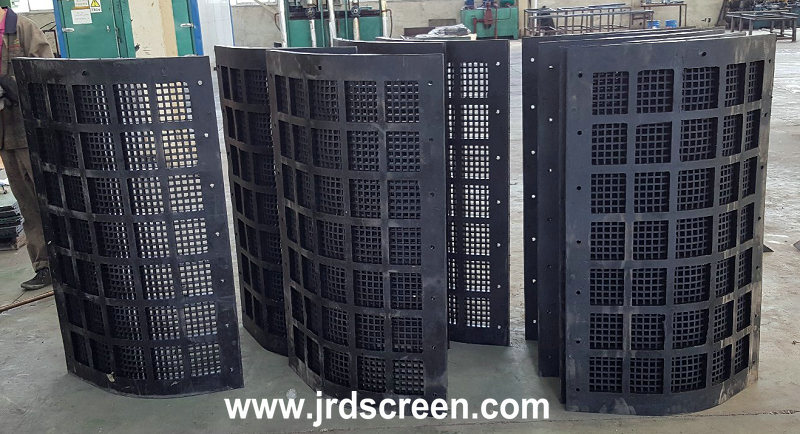

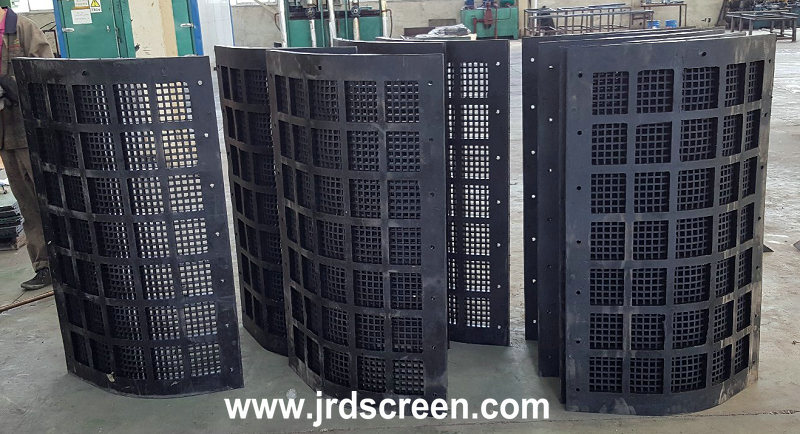

The Main Material Is Wear-Resistant Rubber, With The Hardness Ranging From 35 Shore A To 65 Shore A. It Can Produce Pure Rubber Sieve Bends, Rubber Steel Frame Sieve Bends And Rubber Wire Rope Sieve Bends. According To The Different Use Environment And Machine Characteristics, The Rubber Shaker Screen Bends With Different Structure Is Selected.

Most Of The Mesh Adopts The Vertical Square And Rectangle Structure, And The Cone Structure Mesh Is Also Common.

The Opening Rate Can Be Between 20% And 75%, Which Can Be Fully Used In Various Screening Environments.

In Many Cases, The Thickness Of The Frame Is Far Greater Than The Thickness Of The Mesh Rubber, Which Saves The Waste Of Materials To The Greatest Extent And Is More Environmentally Friendly.

The Shape And Size Can Be Customized According To The Needs Of The Bends Surface Of The Shaking Screen Machine. For Small Machines, The Large-Scale Integral Screen Bends Is Often Used To Facilitate Installation, But For Large Machines, The Small-Scale Splicing Structure Is Often Used To Reduce The Waste Of The Worn Screen Bends. Our Company's Shaking Screen Rubber Screen Rice Can Be Used In Various Models.

The Industries Are Mostly Tailing Engineering, Coal Mine Classification System, Power Plant Ash Separation System, Petroleum Solid Medium Separation System, Metallurgical Screening System, Chemical Primary Material Separation System.

Performance Advantages

Excellent Wear Resistance

The Wear-Resistant Rubber Belongs To The Soft Wear-Resistant Elastomer Structure, Which Can Effectively Play The Role Of Buffer And Show The Best State In The High Frequency Shaker Screening Work. Up To 4500 Hours Of Working Life, And By Our Company To Provide Quality Assurance. Furthermore, The Repair Frequency Of The Machine By The Owner Is Further Reduced, So As To Save The Cost For The User. Thickened Sieve Bends Can Deal With Very Bad Separation Environment.

An Introduction To The Screening Of Materials With High Oil Content

Wear Resistant Natural Rubber Is Generally Not Oil-Resistant, And It Will Swell When Encountering Oil. Therefore, For Screening Materials With Slightly Higher Oil Content, Natural Rubber Is Generally Not Used, But Butyl Rubber. Compared With Polyurethane, Rubber Has Poor Water Resistance. Therefore, The Rubber Shaking Screen Bends Is Generally Used In The Working Environment Of Dry Screening.

Good Corrosion Resistance.

For The Ph Value Is More Than 3, Or Ph Value Is Less Than 12, It Can Play A Very Good Corrosion Resistance. The Screening Bends Of Iron And Steel Materials Will Be Severely Corroded In Direct Contact With Acid Solution, Which Belongs To Chemical Replacement Reaction, While Rubber Materials Can Effectively Avoid This Situation.

Good Flame Retardancy

Rubber As A Whole Belongs To Incombustible Material. It Doesn't Burn Like Plastic. Rubber Can Effectively Block Combustion. Avoid Natural Phenomena Due To Excessive Temperature During Use.

Non Toxic And Harmless.

The Basic Material Of Rubber Is Natural Organic Matter, Which Is Taken From Nature And Belongs To Renewable Resources. There Is No Harm To Human Body, Even For Many Foods, It Can Be Made Into Edible Rubber, So It Is Harmless To Human. The Grinding Residue Of Rubber Is Filled With Flexible Particles, Which Will Not Form Adhesive Adhesion To The Screen Bends Itself, Thus Reducing The Harm To The Machine.