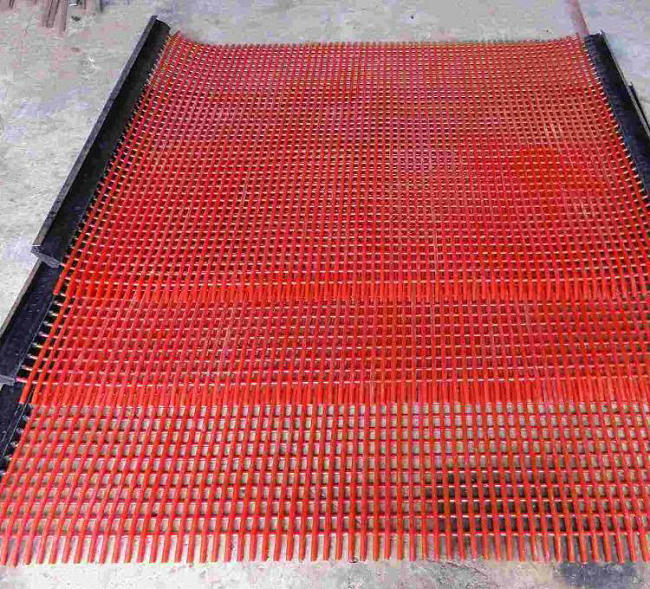

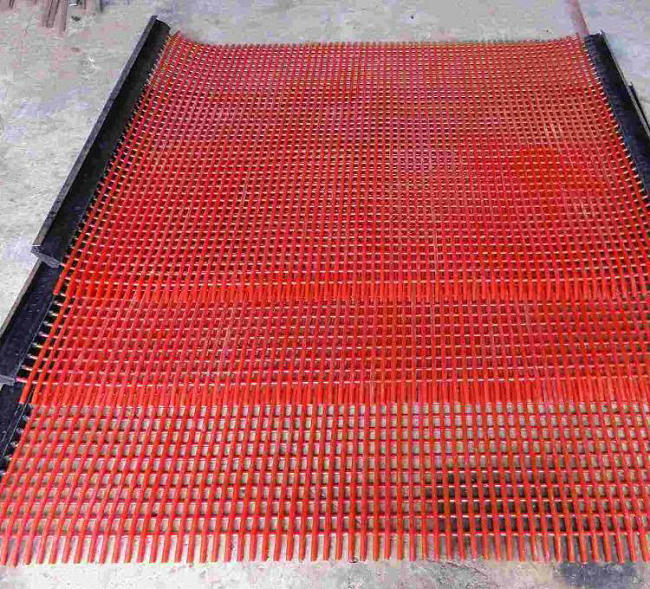

Polyurethane Wire Screen Is A PU Plate Made Of Polyurethane Wire, Either In Sheet Form Or In Roll Form. It Is Made Of High-Quality Q235 Welded Wire Screen, Which Has High Strength Bearing Capacity And High Wear-Resistant Coefficient By Molding Casting Polyurethane.

Specific Production Process:

1. Take Q235, Q195 Carbon Steel Wire Rod As The Basic Raw Material, And Pull It To The Corresponding Diameter According To The Requirements Of The Drawing. Generally, It Is The Best Condition From 3mm To 5mm In Diameter, Which Will Not Lose The Pressure Bearing Capacity Due To The Thin Wire Diameter, Nor Increase The Weight And Installation Difficulty Due To The Thick Wire Diameter.

2. According To The Requirements Of The Drawing, It Is Made Into a Screen Plate . Generally Welded Wire Screen , But Also Woven Wire Plate. Prepare The Framework For Polyurethane Coating.

3. The Welded Steel Wire Screen Needs To Be Pickled, Degreased, Derusted And Cleaned.

4. Put The Prepared Welded Steel Wire Screen Plate In The Pre Prepared Mold, And Use The Liquid CPU Polyurethane Casting With High Wear Resistance To Form. For The Convenience Of Customers, The Color Of Polyurethane Can Be Specified By The Owner.

5. After One Piece After One Piece Of Polyurethane Plate Is Completed, Our Company Will Conduct Unified Vulcanization And Pressurization Molding.

6.After The Perfect Packaging, The Exquisite And Strict Polyurethane Screen Plate Will Be Presented To The Owner By Sea Or Air.

Main Performance:

Strong Bearing Capacity

As The Welded Carbon Steel Wire Screen Plate Is The Steel Frame, The Weight Bearing Capacity Of The Whole Plate Of Polyurethane Wire Screen Plate Is Equal To That Of The Metal Wire Screen . It Can Withstand The Screening Work Of High Weight Materials.

High Wear Resistance

Polyurethane Wire Screen Plate Surface, Mainly Polyurethane And Material Contact, So The Overall Performance Inherits The High Wear Resistance Of Polyurethane. Under The Same Conditions, Polyurethane Elastomer Can Show Excellent Wear Resistance.

Excellent Elasticity.

One Is That The Carbon Steel Embedded Wire Screen Plate Has High Overall Elasticity Due To Its Overall Tension. The Other Is That Polyurethane Elastomer Itself Is a Soft And Wear-Resistant Material With Excellent Elasticity. Under The Combined Action Of The Two, The Urethane Screen Plate Shows Excellent Elastic Properties.

Polyurethane Plate Surface Is Very Flat

After CNC Machining, The Casting Steel Structure Mould Ensures That The Size Of Polyurethane Wire Screen Is Formed In Strict Accordance With The Drawing; High Temperature Vulcanization Process, Low Temperature Holding Bin Delay Vulcanization Time, Greatly Reducing The Size Error Caused By The Shrinkage Of Polyurethane. In Strict Accordance With The Production And Processing Process, To Promote The Polyurethane Plate Flat.

Polyurethane Plate Number Is Even,

The Embedded Steel Structure Wire Plate Adopts Mature Production Technology To Ensure That The Plate Number Of Polyurethane Wire Screen Plate Surface Is Uniform And Low Error From The Beginning, So As To Ensure That The Plate Number After Polyurethane Vulcanization Molding Is Perfect And Error Free.

The Structure Is Firm.

Polyurethane Wire Plate Foundation Frame Adopts Advanced Integral Argon Arc Welding Foundation, Fully Automatic Mechanized Work, To Ensure That The Welding Points Are Firm, No Missing Welding, Hard And Stable, As a Prerequisite To Ensure That The PU Screen Plate Structure Is Stable And Firm.