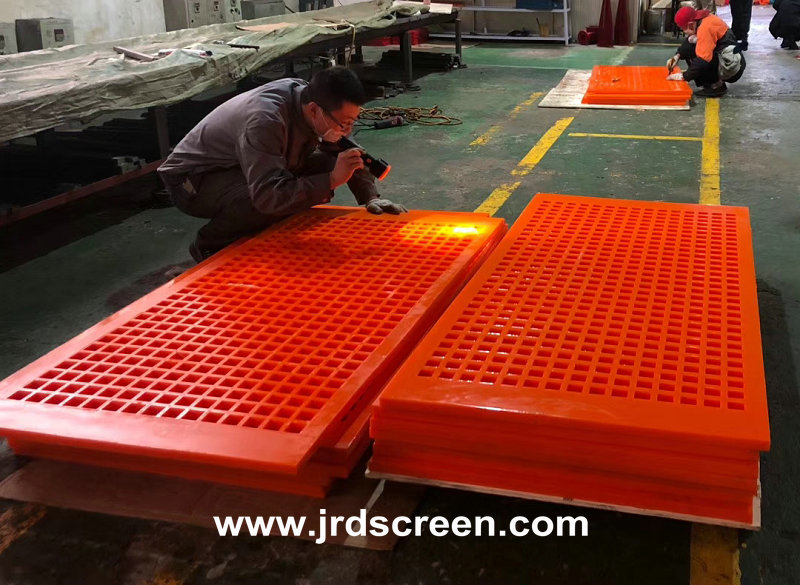

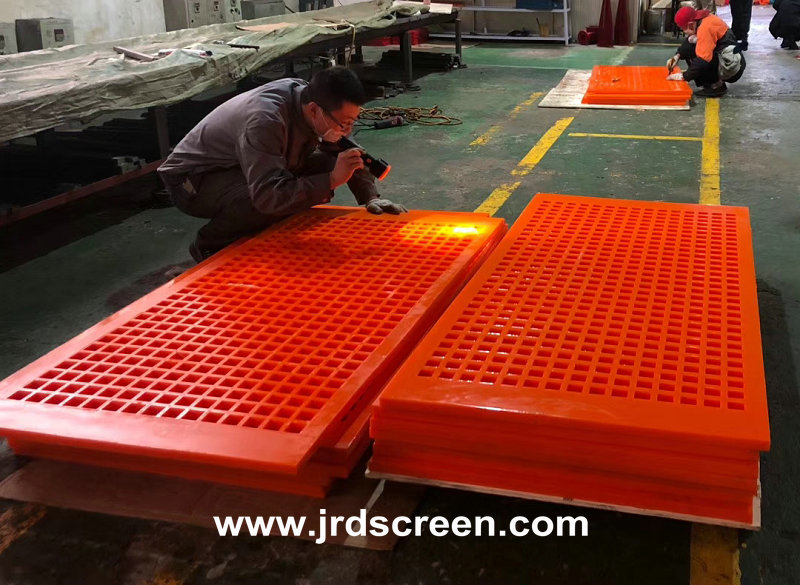

Polyurethane Shaker Screen Sheet Is Made Of Wear-Resistant Polyurethane Material With Holes / Mesh On Its Surface. The Utility Model Belongs To a Fine Pore Polyurethane Shaker Screen Of a High Frequency Shaker Screen.

In The Field Of Screening, Metal Screens Can Be Effectively Replaced. It Is Wear-Resistant, Non Corrosive And Self-Cleaning. Tapered Mesh Can Improve Efficiency, Reduce Noise And Make Work More Comfortable. The Advantages Of Working In Humid Conditions Are Particularly Prominent.

Polyurethane Materials : The Hardness Of Polyurethane Elastomer Is 30 Shore A To 90 Shore A, And The Screen Sheet Is Inlaid With Steel Framework To Ensure Its Greater Bearing Capacity.

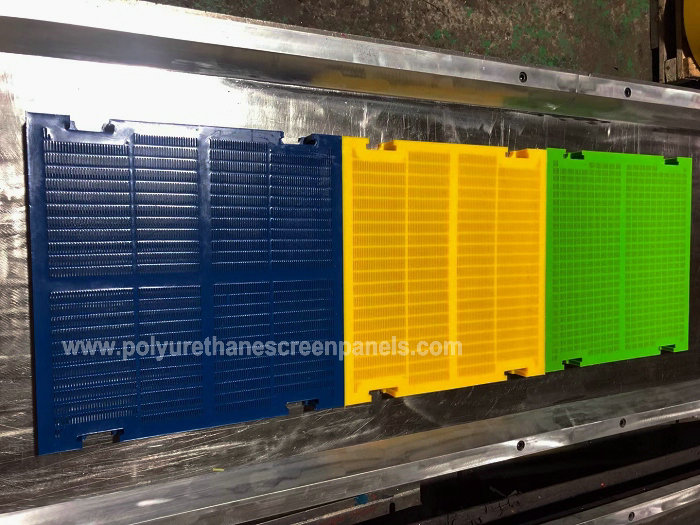

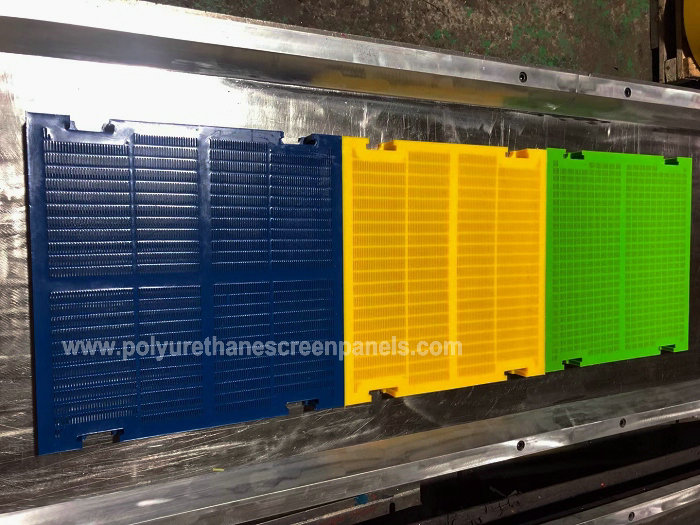

Mesh/Holes Shape : Rectangle, Square, Circle, Ellipse, Strip, Etc.

Opening Effect : 0.1mm-40mm (Square Hole, Strip Hole)

Sieve Sheet Thickness : Generally 25 mm-100 mm

External Dimension : 305mm x 610mm, The External Dimension Is Determined According To The Model Of Shaker Screen.

Application Machine And Equipment : Shaker Screen, Cylinder Screen.

Industry : Mining Screening Industry, Coal Washing Plant, Power Plant, Petroleum Refining, Metallurgical Equipment, Chemical Plant, Etc.

Main Features

High Wear Resistance.

Polyurethane Elastomer Material Has Good Wear Resistance And Impact Resistance. In Frequent Use, It Can Keep a Good Working Condition, And Ensure That The Screen Can Be Used For a Long Time Without Damage, And Improve The Service Life. High Wear Resistance Ensures Long Working Time. The Probability Of Maintenance Is Greatly Reduced, The Load Capacity Is Super Strong, And The Work Will Not Be Damaged Under The Bad Environment. A Lot Of Manpower, Material And Financial Resources Have Been Saved.

Good Hydrolysis Resistance And Oil Swelling Resistance.

Polyurethane Shaker Screen Sheet Can Be Used Well With Water And Oil. The Lower The Oil Content Of The Material Is, The Lower The Friction Coefficient Between The Feed And The Screen Sheet Surface Is, Which Effectively Slows Down The Adhesion Of The Wet Solid Particles On The Screen Sheet, Thus Improving The Screening Efficiency, Reducing The Wear Of The Screen Sheet And Prolonging The Working Time.

It Is Chemical Resistant, Flame Retardant, Non-Toxic, Colorless, Tasteless And Harmless.

The Unique And Professional High-Performance Design Of Polyurethane Screen Sheet Effectively Avoids The Blocking Of Screen Sheet Mesh And Well Controls The Particle Diameter Of The Material.

Reduce Noise Pollution

As Polyurethane Itself Is An Elastomer, It Can Effectively Absorb Noise. In Addition, Due To The Size Of Sieve Sheet Is Too Large, The Material Will Not Be Damaged When Shaking. Polyurethane Sieve Sheet Has The Characteristics Of Multiple Shaker, Which Can Self Clean And Improve The Working Efficiency.

The Surface Is Smooth.

Compared With The Woven Shake Screen, The Polyurethane Screen Has a Smooth Surface, Which Reduces The Occurrence Of Nailing And Blocking. Different Apertures And Different Shapes Of Apertures Can Adapt To Different Material Screening, Thus Improving The Working Efficiency Of Polyurethane Screen Sheet.

Easy To Use.

Elasticity Is The Most Obvious Characteristic Of Polyurethane Sheet. There Are Many Kinds Of Connection Modes To Choose, Which Are Easy To Install And Fix. Polyurethane Sieve Sheet Lock Connection Is Better Than Bolt Connection, Which Makes It Easier To Replace Worn Sieve. It Can Save Energy, Reduce The Probability Of Waste Products And Improve The Use Space. The Weight Of The Sieve Sheet Poured With Polyurethane Is Much Lighter Than That Of The Steel Sieve Sheet. Greatly Reduce The Load Of The Shaker Machine, Save Energy, And Extend The Service Life Of The Whole Shaking Screen.

Application Fields And Usage Specifications.

Polyurethane Shaking Sheet Has Various Apertures, Sizes And Types. Different Sieve Sheet Are Used According To Different Dry And Wet Materials. In Addition, There Are A Variety Of Connection Modes, Which Can Be Installed On Various Shaking Screens And Cylindrical Screens.